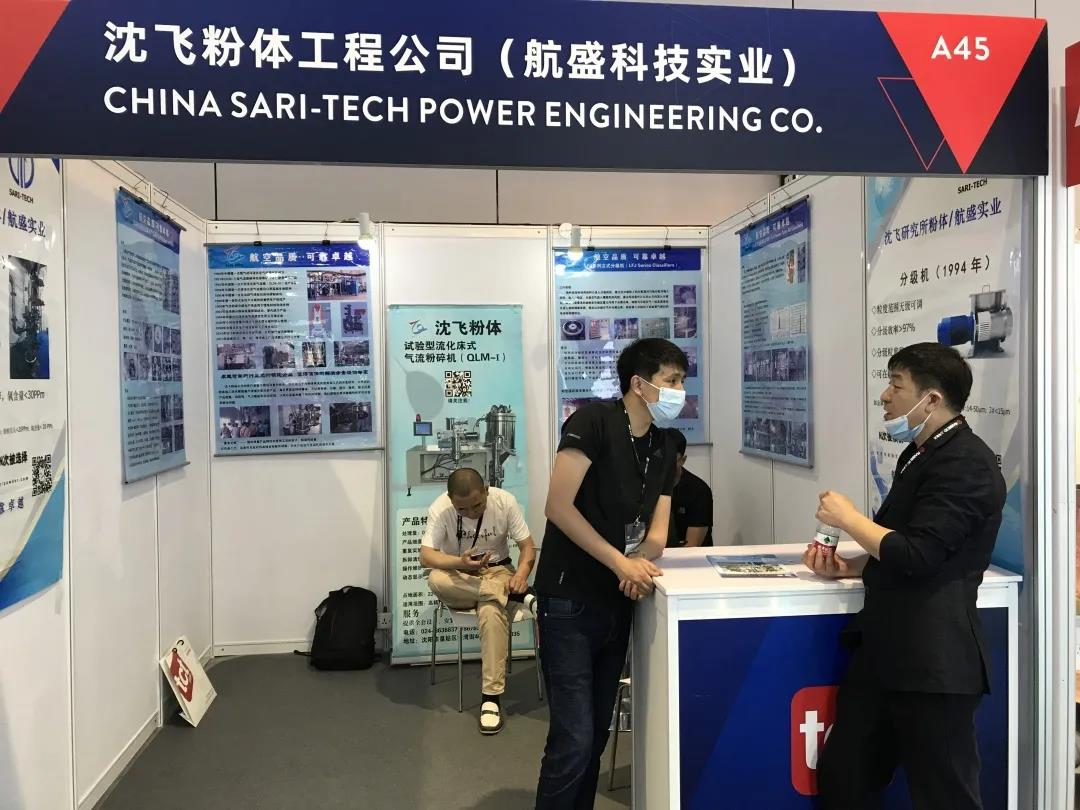

Shen Fei powder participated in the 3-day Asia 3D printing, material adding and manufacturing exhibition and TCT Asia Summit (hereinafter referred to as "TCT Asia Exhibition") from May 26 to 28. The exhibition is composed of the most 3D printing technology and service providers and industry pioneers at home and abroad.

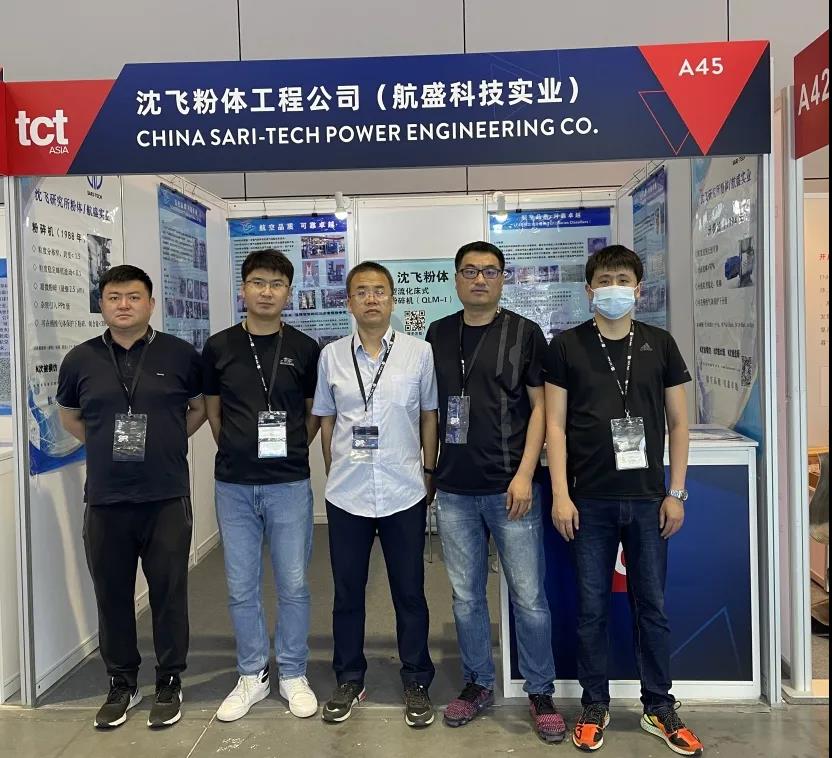

Shenfei powder attaches great importance to the exhibition. The two leaders visited the exhibition site in person to understand the market demand and grasp the market dynamics, and gave specific guidance to the project manager of Shenfei powder participating in the exhibition.

It is required to take every link and detail seriously, do deep, detailed and practical work, and concentrate the company's resources on improving R & D for the difficulties and pain points of the material adding industry. We will do a good job in the technological innovation of our company to ensure that Shenfei powder is developing and growing in the process of development.

Because of the hot 3D printing market, its recognition has been constantly improved. At the same time, Shen Fei powder also made a great difference at the exhibition. From the key elements of the overall performance, finished product rate, processing capacity, oxygen increment and fluidity of the equipment, the new equipment suitable for 3D printing materials is displayed and introduced, which attracts many new and old customers to visit and consult.

Customers who entered the exhibition hall are in continuous stream. More than 100 customers come to the exhibition site to consult Shenfei's new equipment. The project manager of Shenfei powder will give you detailed answers.

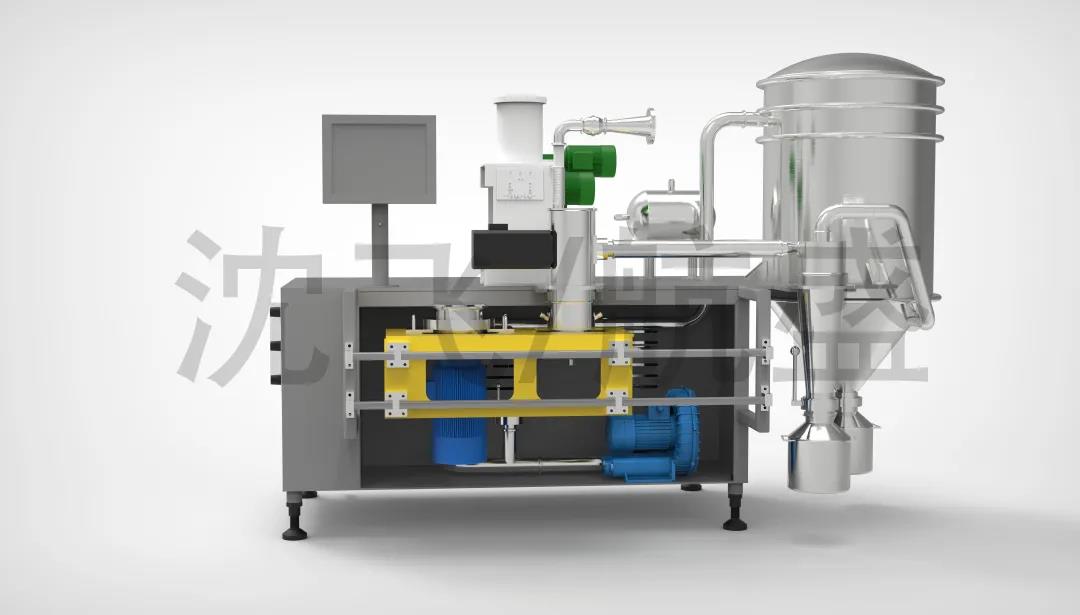

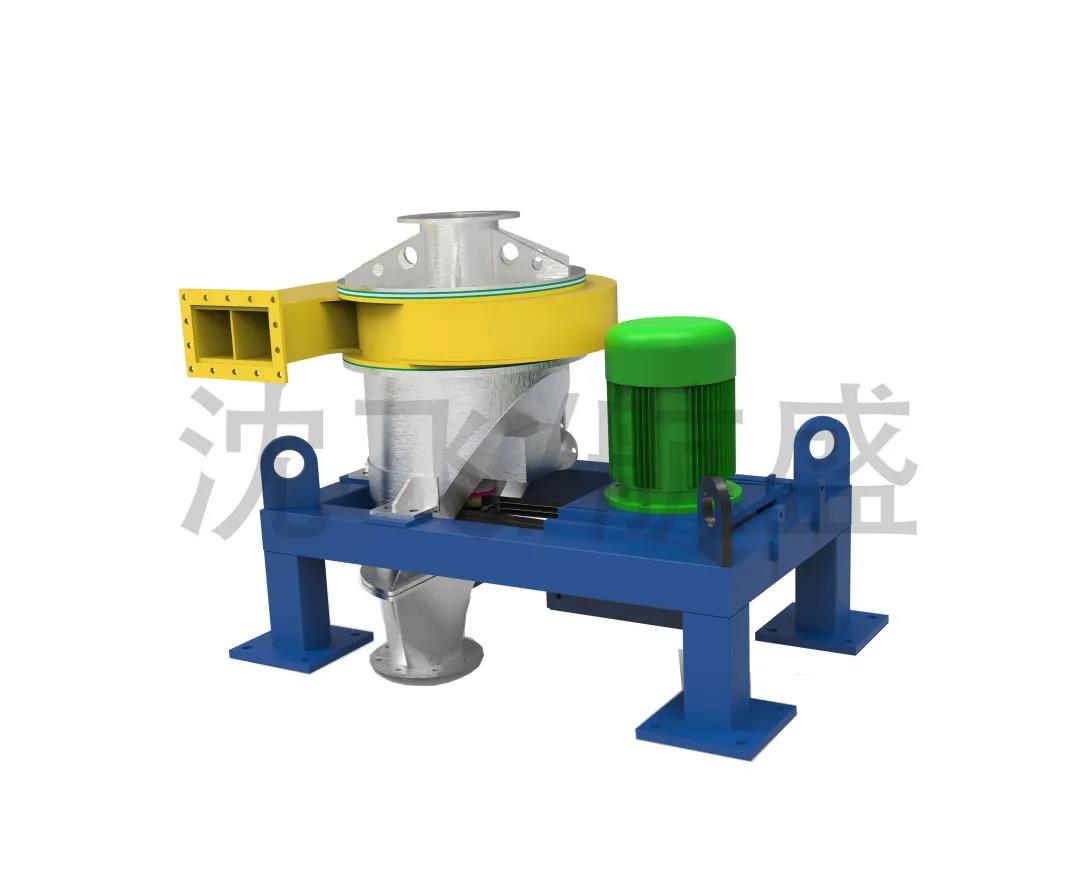

Air flow crusher

The air flow depolymerization pulverizer provided by Shenfei powder is suitable for crushing 3D printing materials. The pressure of the pulverizer is adjustable, which is suitable for metal powder shaping, improving the ball degree, increasing the fluidity of the product and no pollution.

The air flow crusher can be used for open-loop air, closed-loop nitrogen / argon (oil-free argon compressor is recommended), etc. the ambient oxygen content can be controlled within 50ppm, which has significant effect in the treatment of micro sphere.

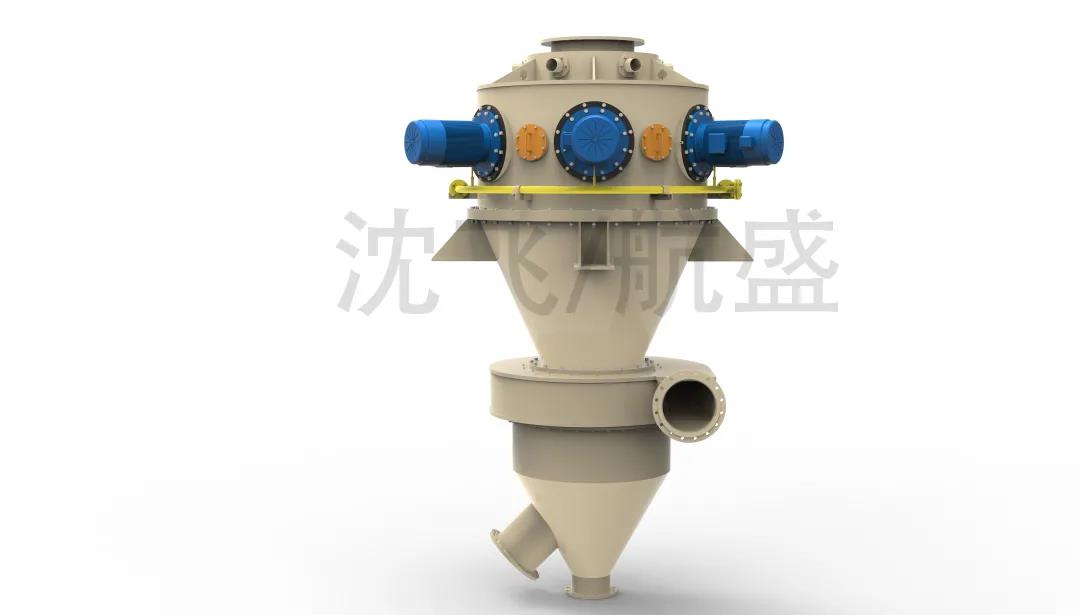

classifier

After the 3D printing powder preparation, the most commonly used equipment is the classifier. For some active metals, it can be classified in the non oxygen state, and the ambient oxygen content is controlled at about 50ppm.

The oxygen increment of the graded metal powder is low. The particles of micro sphere will be reduced and the fluidity will increase by the material passing through the grading wheel. No need to mix again, and the particle size is uniform.

Shen Fei's classifier is divided into fjj series horizontal turbine classifier and lfj series vertical classifier.

It can remove the fine or coarse powder, grading line and cutting point; Frequency control ensures uniform feeding, and Roots fan ensures the stability of flow field.

Horizontal classifier is suitable for cutting 15 micro meter grain size section, with higher cutting accuracy, and can be adjusted arbitrarily at 10-20 μ M.

Vertical classifier is suitable for cutting 53 micro meter grain size section, with higher cutting precision and adjustable 53-70 μ M.

Shenfei powder is introduced in this exhibition, which is suitable for 3D printing industry air flow pulverizer, classifier and mechanical grinding. These equipment are well received by all of you. Many industry elites consult and exchange with the project manager of Shenfei powder.

After detailed communication, Jiangsu willari New Material Technology Co., Ltd., Changsha Weite material manufacturing technology Co., Ltd., Liaoning Guanda New Material Technology Co., Ltd., panstar new alloy material (Changzhou) Co., Ltd. and Shenfei powder have been communicated in detail, and further understand the details of equipment and have a significant cooperation intention.

The general manager of new materials of Anhui Zhongti and the project manager of Shenfei have a good communication and are very interested in the finished product rate of classification. After the meeting, we will conduct material arrangement experiment with Shenfei.

Nanjing Shangji added materials manufacturing Research Institute Co., Ltd. has great interest in f1.5 closed-loop air flow mill of our company, and has the intention to purchase later. AVIC mett, China Weapons Institute and Guangzhou have established contact with Shenfei in the follow-up, and they have the intention of cooperation.

The project manager of Shenfei powder always communicates with customers with sincere attitude, respects the basic needs of customers as the concept, reliable product quality as the principle, and serves customers on the basis of perfect after-sales service.

Shenfei powder market, R & D, sales, manufacturing and service are customer-oriented, customer-centered, continuous change, management and continuous improvement. This exhibition demonstrated the strength of Shenfei powder, and also received the recognition of our products and equipment and brands by the majority of customers. Thank you very much for your trust and support to our customers. I look forward to meeting again at TCT next year!