The third carbon materials technology summit forum was held in Shangri La Hotel, Ningbo, Zhejiang Province from May 19 to 21, 2021.

The conference is sponsored by China chemical and physical power industry association, CO sponsored by Ningbo Institute of materials technology and engineering, Chinese Academy of Sciences and Wenzhou University. It will focus on the technology and research of carbon materials as "high performance electrode material + new conductive additive".

Background of the meeting

As we all know, carbon materials are widely used in the cathode materials of lithium batteries. Its expansion performance largely determines the cycle life of the battery. The specific capacity and efficiency have a great influence on the battery capacity. The compaction density, thickness of electrode also affect the ratio performance of the battery, and the key influence on the performance of the battery determines that carbon is a crucial raw material.

This conference will focus on the following aspects: the technology and research of carbon as "high performance electrode material + new conductive additive".

1) Carbon based negative material of lithium-ion battery

2) Silicon carbon negative material of lithium ion battery

3) Lithium carbon anode material for lithium metal battery

4) Soft and hard carbon, natural graphite and artificial graphite anode materials for fast charging battery

5) Lithium titanate cathode material

6) Carbon coated aluminum foil, copper foil collecting fluid

7) Sulfur carbon composite positive material for lithium sulfur battery

8) Soft / hard composite carbon anode material for high power lithium ion battery

9) Carbon nanotubes and graphene composite energy storage materials

10) New porous carbon materials for super capacitors

11) Research progress and application of conductive materials such as conductive carbon black, Cochin black, nano carbon fiber and so on

12) Composite conductive slurry for lithium ion battery

13) Application of carbon nanotubes and graphene in lithium-ion battery system

14) Study on dispersion technology of high performance carbon materials

[meeting time]

May 19-21, 2021

[meeting place]

No.88, Yuyuan street, Jiangdong District, Ningbo

Shangri-La Hotel Ningbo

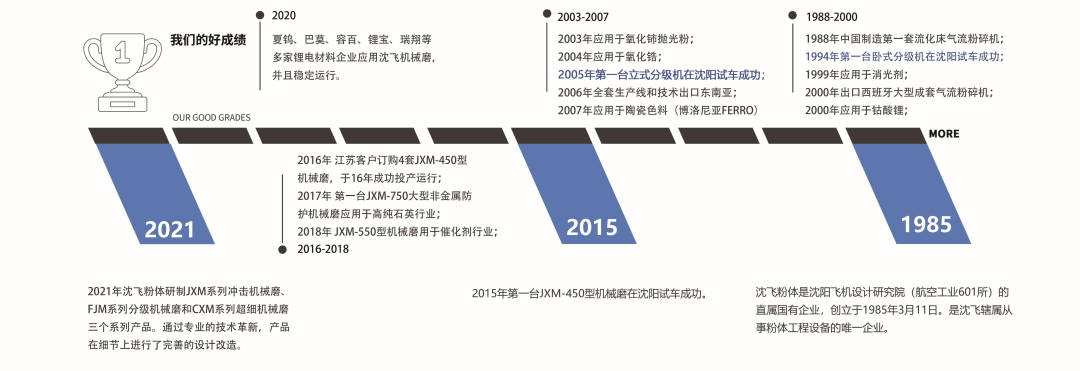

Shenfei / Hangsheng as support unit

Shenfei powder participated in the meeting as a supporting unit.

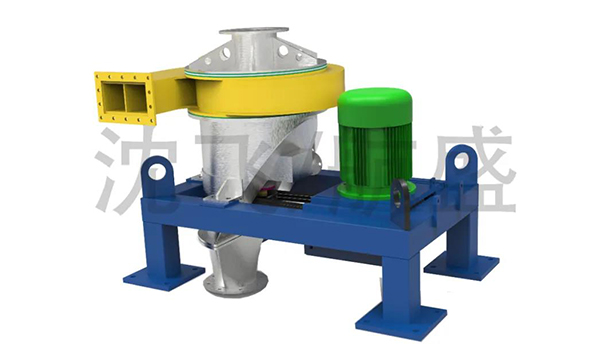

Shenfei powder is the designated partner of major enterprises, providing customers with high-quality crushing equipment products and services, mainly including vertical classifier, mechanical grinding, air classifier and other products.

It is applicable to special equipment for crushing and grading silicon based negative electrode materials ★

According to the different characteristics of silicon and graphite, Shenfei powder has developed and produced ultrafine grinding and grading equipment.

At the same time, Shenfei powder proposed a solution to the treatment process of covering the surface of silicon particles with different particles.

The cost of materials is reduced, and the electron density and wettability are improved. The high yield of the finished product makes the atmosphere on the surface of the particles better coated into a film.

Vertical classifier

·Grading lines and Cut Vertices

·Negative pressure operation of the system, no dust leakage

·Frequency conversion speed control ensures uniform feeding

·Roots fan ensures the stability of flow field

·Cooperate with the crusher

·Better material circulation and accuracy

Mechanical grinding

·The internal parts are made of high hardness and wear-resistant materials, which are durable

·Ceramic structure, tungsten carbide treatment on detail parts

·Magnetic material increment < 5ppb

·Optimized ceramic ring gear, effective control over grinding

·Optimize the sealing structure of ground gas, and concentrate the particle size distribution

·Effective cooling of water cooled cooler in closed loop system

·Quick disassembly and easy cleaning of cooler structure

Air flow mill

·It is suitable for depolymerization and comminution of all kinds of lithium positive / negative materials and precursor

·The increment of magnetic material can be controlled at 0-5ppb, and the batch repeatability is good

·Have a variety of design working modes (open and closed type; Positive pressure, negative pressure, etc.)

·Small fluctuation to meet the material demand of lithium battery

·All ceramic protection, magnetic control position

·High information level, can realize LAN information collection and mobile control

Top line brands in China's supply of ultrafine crushing and grading equipment: ★

Welcome all enterprises at home and abroad to participate in this meeting to discuss the technology and development of carbon materials for battery together, make efforts and contributions to the development of the industry. Shenfei powder is waiting for the presence of customers and partners.