SAC powder exhibits CIBF

SAC Powder Airflow Mill has attracted much attention in the powder market. It is not only a first-class brand in the field of ultra-fine grinding equipment supply in China, but also the designated partner of various well-known enterprises.

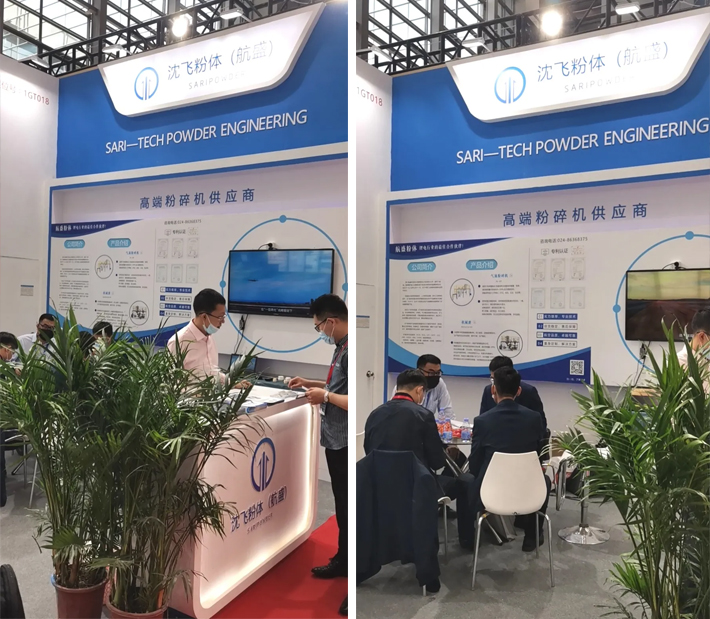

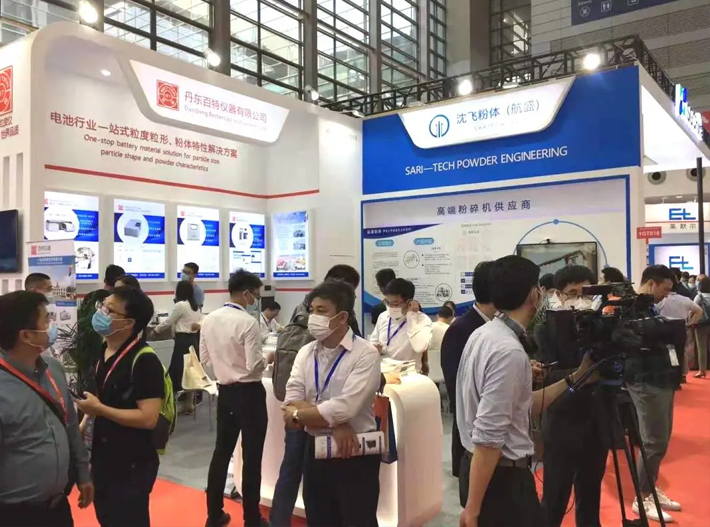

At the CIBF International Battery Exhibition, SAC Powder showed three series products of mechanical grinding in a comprehensive and detailed way.

The CIBF to attract the customers to visit, the exhibition also attracted extensive attention of the whole industry customers, have to come to consult. The manager of the shenyang aircraft powder were warmly received and carefully.

Since 1985, SAC Powder has been committed to the research, development and manufacturing of grinding equipment. In 2015, the first JXM-450 mechanical mill was successfully tested in Shenyang.

In 2021, SAC Powder developed three series of JXM series impact mechanical mill, FJM series classification mechanical mill and CXM series ultra-fine mechanical mill. Through the professional technical innovation, the product has carried on the perfect design transformation in details.

JXM series impact mechanical mill

A JMX series impact depolymerization of grinding machine is suitable for general materials. The internal configuration is divided into ceramic mechanical grinding and metal material mechanical grinding.

02

FJM series grading mechanical grinding

FJM series sizing machine is suitable for grinding depolymerization loosely together material, higher efficiency, lower energy consumption. It is suitable for reducing the content of fine powder in the depolymerization process of lithium cathode materials.

03

CXM series ultrafine mechanical grinding

CXM series ultrafine mechanical mill is suitable for depolymerization of ultrafine powder products and has strict requirements on DMAX index.

04

Product advantage in details

1. Optimized design of feeding form of mechanical mill, spiral horizontal feeding mode and forced feeding mode of eddy current air pump.

2. Ceramic structure, detail parts are sprayed with tungsten carbide treatment, magnetic foreign body increment <5PPb.

3. Optimize the structure of ceramic gear ring and tool head to effectively control over crushing.

4. Optimize the gas seal structure, which can effectively control on3dmax, particle size distribution is more concentrated.

5. The secondary dust filter with reflexive blowing function, equipped with manual sewage outlet with differential pressure sensor.

6. Closed-loop system water-cooled cooler cooling effectively, cooler structure quick disassembly and easy cleaning, stable monitoring.

7. All metal material mechanical grinding, widely used in food, medicine, chemical industry and other fields.

The SAC powder exhibits are mainly the core products of mechanical grinding parts and airflow grinding, which let customers appreciate the absolute style of SAC in the field of ultra-fine grinding.

C w, mo, capacitors, and a number of li-ion battery materials in lithium treasure enterprise use sac mechanical grinding equipment. After 35 years of accumulation of precipitation and the strict inspection of lithium electricity market, sac powder products are widely used in lithium-ion battery industry, and won the customers highly recognized!

Through this exhibition, not only let customers understand the professional products and equipment of SAC powder, but also let customers contact with zero distance, feel the influence of SAC brand!

Powder industry leader, air mill high-end brand - SAC powder.