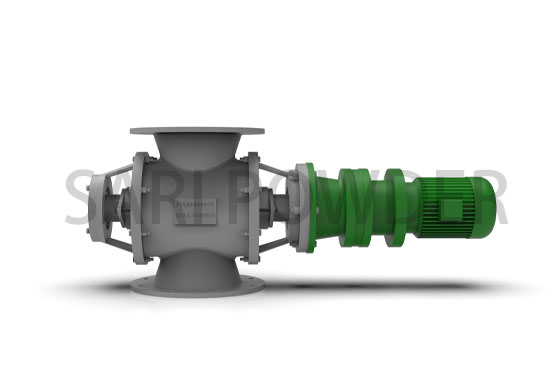

Discharge valve, also known as star ash discharge valve, impeller feeder, fan, etc., can be divided into two kinds of rigidity and elasticity according to different blades. It is an important part of the uniform and continuous batching, conveying and unloading in the mechanization and automatic control system. It depends on the gravity of the material and the discharge valve working mechanism of the forced effect, will be stored in the warehouse of the material discharged and continuous uniform input to the next device.

Discharge valve, also known as star ash discharge valve, impeller feeder, fan, etc., can be divided into two kinds of rigidity and elasticity according to different blades. It is an important part of the uniform and continuous batching, conveying and unloading in the mechanization and automatic control system. It depends on the gravity of the material and the discharge valve working mechanism of the forced effect, will be stored in the warehouse of the material discharged and continuous uniform input to the next device.

Discharge valve features

◇ Compact structure, small size, large processing capacity, easy maintenance and operation

◇Special structure design and production process to achieve good gas locking effect

◇Suitable for all kinds of loose and non-viscous dry materials, round or square import and export

◇Powder material quantitative supply (discharge) material or can be used for pressure or suction type pneumatic conveying device

◇ According to the characteristics of the material, explosion-proof motor, frequency control or electromagnetic speed control motor can be equipped

◇ By turning, milling and assembling piece by piece, high precision air locking and feeding discharge effect can be guaranteed

◇Special design of shaft seal (gland type, mechanical type, gas seal, etc.) applicable to different working conditions